Design and Development of a Carburetor to Run an Otto Engine on Producer Gas | 2019

- Nirosh Jayasuriya

- May 31, 2020

- 2 min read

Updated: Jun 7, 2020

University of Moratuwa, Supervised by Dr. J.G.A.S Jayasekara

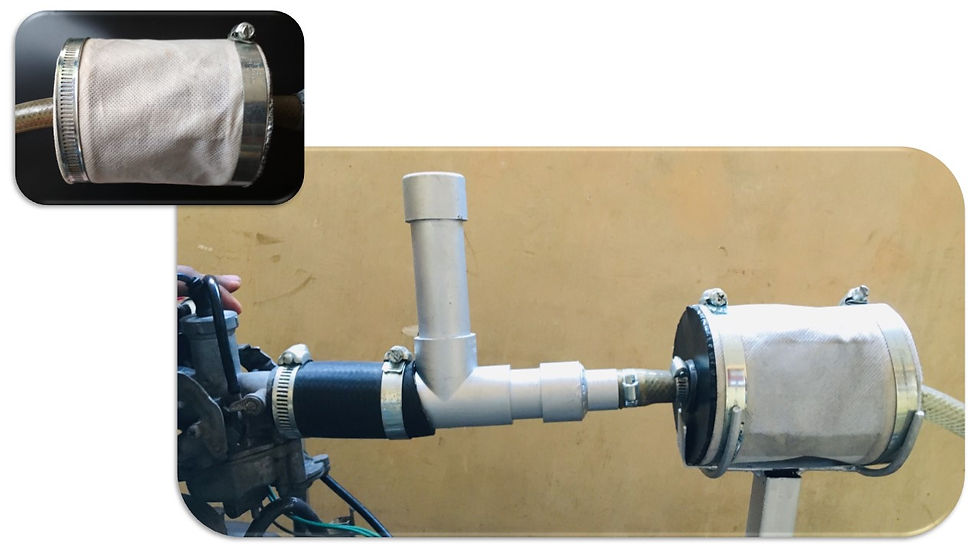

This project is related to design and development of a carburetor for producer gas to successfully obtain worked for IC engine operation. So far from the literature review performed we have identified that producer gas is a low energy density gaseous fuel. The carburetors were not available for such fuels. The stoichiometric air-fuel ratio for producer gas is about 1.2 /1.4. The envisaged features in the gas carburetor are the ability to maintain the required air-fuel ratio of 1.3:1 with load or throttle variation. The carburetor should be simple in design and does not have moving components. It has a separate port for air and fuel, where the individual ports could be modified or tuned to achieve the required air-to-fuel ratio. The carburetors available for other gaseous fuels, namely natural gas, biogas, and landfill gas, are unsuitable due to widely different stoichiometric air-fuel requirements. The stoichiometric air-fuel ratio varies between 10 and 6 (on a volume basis) for fuels such as natural gas and biogas/landfill gas based on the methane content in the gas. Our design is very closely related above gas carburetors. Our main objective being, develop gas carburetor using pre-mixed combustion technologies. Further a gas filtering system was designed and fabricated.

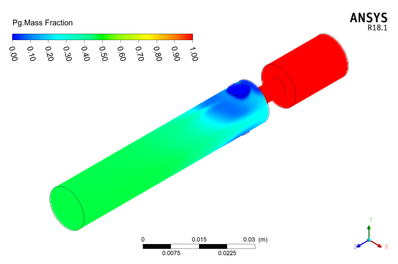

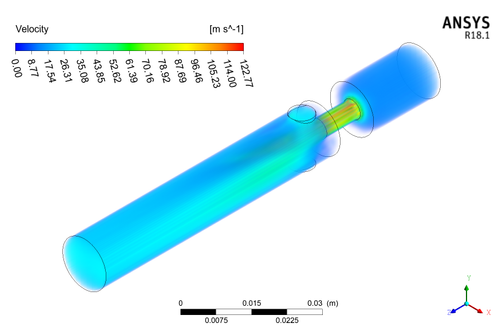

The final carburetor design was achieved through few failure models. However, the final model was able to operate an IC engine without any failure. Series of CFD simulations (Ansys Fluent) was used to study the gas, fuel mixing procedure and to evaluate the air fuel ratio at the carburetor outlet port. Some of simulation results are shown below pictures.

Finally, we had to design control system for control the RPM of engine using Arduino.

Comments